Reduce noise, vibration, maintenance & damage.

Reduce noise, vibration, maintenance & damage.

How it Works?

The Sidewinder™ belt drag conveyor is one of the most versatile drag conveyors on the market. The Sidewinder™ is the only drag conveyor to utilize a belt instead of a chain.

The belt lies vertical in the trough and flights are attached to the belt. A motorized pulley system pulls the belt and flights smoothly through the trough, thus reducing noise, vibration, maintenance and damage.

The belt provides smooth movement through the discharge points and around corners. Round-bottom or flat-bottom troughs are available.

How it Works?

The Sidewinder™ belt drag conveyor is one of the most versatile drag conveyors on the market. The Sidewinder™ is the only drag conveyor to utilize a belt instead of a chain.

How it Works?

The Sidewinder™ belt drag conveyor is one of the most versatile drag conveyors on the market. The Sidewinder™ is the only drag conveyor to utilize a belt instead of a chain.

The belt lies vertical in the trough and flights are attached to the belt. A motorized pulley system pulls the belt and flights smoothly through the trough, thus reducing noise, vibration, maintenance and damage.

The belt provides smooth movement through the discharge points and around corners. Round-bottom or flat-bottom troughs are available.

The belt lies vertical in the trough and flights are attached to the belt. A motorized pulley system pulls the belt and flights smoothly through the trough, thus reducing noise, vibration, maintenance and damage.

The belt provides smooth movement through the discharge points and around corners. Round-bottom or flat-bottom troughs are available.

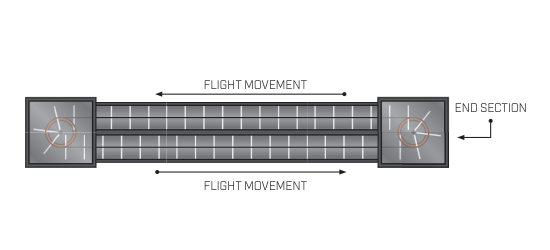

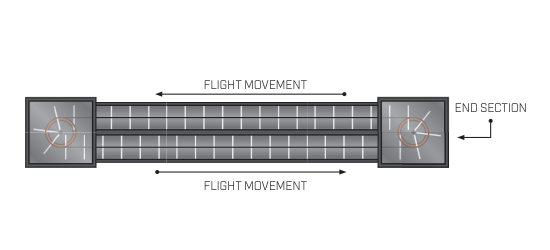

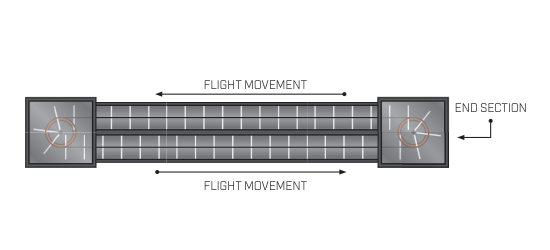

Sidewinder™ Layout

The most common layout for a Sidewinder™ contains two 180° corners and lies parallel to a horizontal plane or at an incline. The belt system is cyclical, because the belt is moving in two directions at the same time.

This common layout has the option of discharging product at both ends, one end, and/or an intermediate discharge points(s). Often, this layout is utilized when installed underneath our Gentle Roll™ screener as a discharge system.

Contact us for Custom layouts that can be designed for your specific application and facility.

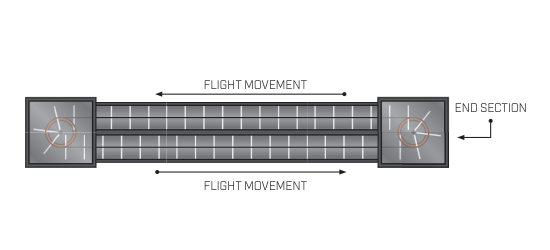

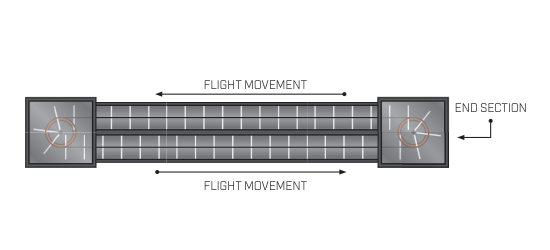

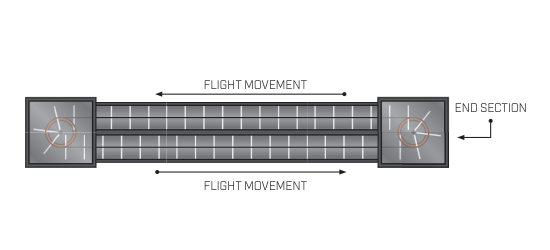

Sidewinder™ Layout

The most common layout for a Sidewinder™ contains two 180° corners and lies parallel to a horizontal plane or at an incline. The belt system is cyclical, because the belt is moving in two directions at the same time.

This common layout has the option of discharging product at both ends, one end, and/or an intermediate discharge points(s). Often, this layout is utilized when installed underneath our Gentle Roll™ screener as a discharge system.

Contact us for Custom layouts that can be designed for your specific application and facility.

Utilizes a Belt instead of a Chain

Simultaneous Movement

Minimum Maintenance

Utilizes a Belt instead of a Chain

Simultaneous Movement

Minimum Maintenance

Sidewinder™ Capabilities

Utilizes a Belt Instead of a Chain

The only drag conveyor to utilize a belt instead of a chain. Each Sidewinder™ provides excellent dust control and uses only the highest quality materials.

Easy Product Entry

The Sidewinder™ integrates inlets on top of the troughs to allow for easy product entry.

Diminishes Product Damage

The Sidewinder™ moves the product in bulk so there is very little product to metal contact, thus diminishing product damage.

Maximizes Product Clean Out

Because the flights perfectly fit in the round-bottom trough, product clean-out during operation is maximized.

Provides Simultaneous Movement

Provides full clean-out, simultaneous movement in both directions, movement of more than one product at a time and high angle range (up to 40° incline).

Minimum Maintenance

The Sidewinder™ reduces noise, vibration, maintenance and damage.